"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

04/04/2019 at 15:26 ē Filed to: None

0

0

17

17

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

04/04/2019 at 15:26 ē Filed to: None |  0 0

|  17 17 |

If you were going to make one of these (you have the controllers, s teppers, a compact router, and the room for either)

The MPCNC (Original)

!!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

or

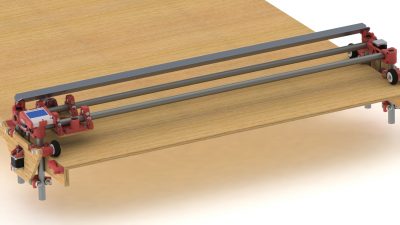

The LowRider

!!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

Which one w ould you choose?

A different DIY CNC device?

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 15:44 |

|

I donít know but Iím interested to hear other opinions as I am just starting to research CNC routers.††

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

04/04/2019 at 15:49 |

|

Yeah Iím having a really hard time choosing between the large X-Y capability of the LowRider or the more capable Z axis of the MPCNC... Either way itíll probabl y go in the basement, which has PLENTY of room... Iíve sort of been thinking about doing a HUGE MPCNC... but then again the design gets ďfloppyĒ with larger X-Y dimensions... ARGH!

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 15:55 |

|

I donít need a huge one... I donít think. Iíve been strongly considering one of the cheap chinese ones from eBay or Ali or whatever. I have a buddy who has one and loves it so far and it was under $300 with both a high speed router head and a laser. But capacity is only 180x300mm with maybe 30mm Z travel (give or take 10mm).

For the little projects Iíd want to use it for thatís probably perfect, at least until I figure out bigger things. But by that point Iíd probably be ready to build one. An EXBOX HEUG ONE!!!

On an unrelated note, how are the lambs?

benjrblant

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

benjrblant

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 16:06 |

|

Can you identify what kind of parts you want to make? materials? these home-gamer CNCís arenít bad for doing lightweight stuff but unlike 3d printers, your enemy here will be deflection. Youíll need some really stiff slides and bars to support the gantry as itís taking mostly lateral motion from cutting on the X/Y plane. Otherwise, youíll need to drastically reduce your feedrates and or take significantly smaller and subsequently more passes.

Iím guessing youíre looking for the most cost-effective option here? Have you looked at the x-carve?

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> benjrblant

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> benjrblant

04/04/2019 at 17:08 |

|

Iím looking at at an all-in cost under $500US for the MPCNC or the LowRider (INCLUDING the Makita RT0701CX router) . X-Carve is ~$ 1900. Speed is not a real concern, as my usage will be a few parts a month, maybe less . Probably mostly in plastics (UHMW) and wood, with a few bits of aluminum here and there. A gain, production speed is of almost zero concern. These two machines use a very similar set of purchased components, price- wise anyway, despite the quite different BOMs. The MPCNC offers greater Z axis range (with the clearance to add a rotary axis if desired ) and a more compact footprint, as well as slightly more reliance on 3D printed parts for structural purposes. The LowRider offers large X-Y axis (potentially up to 4x8 foot full-sheet) , with potentially lower accuracy, lower over-all complexity, but greater reliance on human-built parts for structural and alignment purposes. Also, the Low-Rider has a practical z-axis limit of about 4 inches, vs ~8+ for the MPCNC... I keep thinking Iíve convinced myself I want to go with the MPCNC for reasons of flexibility, but as a farmer the large form factor of the LowRider * might* be more useful in the long run... the MPCNC will require signif icantly more filament and 3D-printer time to complete, but thatí s largely unattended...

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

04/04/2019 at 17:15 |

|

yeah, I do w an t something bigger and more capable than the little Chinese ones, and for about the same cost ó since I have a 3D-Printer already, and am not afraid of assembling my own electronicsó I can build a machine that offers a much more powerful spindle and far larger work area... itís a question of priorities as far as size vs z-axis...

The lambs are largely good, we lost one to an unknown neurological disease that may or may not have been meningeal worm, and we have one sick with what may be meninge al worm, and one that has a mystery pus-filled infection that we are waiting for word from the vet about... but the other 70 are doing well, very bouncy and growing fast. Weíre really hoping thereís grass to feed them on the fie lds soon , as the hay consumption is WAY up. Snow forecast for tonight again though :|

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 17:43 |

|

Well thanks, thatís just great! Now Iím gonna have to look at those links when I get home and probably end up building my own HEUG one . What Iím really interested in is a laser cutter for making foamboard airplanes, though I could use a router for a few things as well. Iím blaming you when I build a 4' x4' machine in the basement...

:)

Iím glad the lambs are doing well and hope the 2 that are ill get better. My cousins should have baby goats soon, canít wait to go up and see the little buggers.

Levitas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Levitas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 17:46 |

|

I spent a number of years working with a full sheet gantry router from Haas, so here are some of my thoughts:

- You may find out very quickly that youíll only be able to work with foams or soft woods. Router spindles spin too fast for a small machine like this to keep the feeds up, and even though the spindle may have the peak power necessary, the drive servos certainly wonít.

- Related to this issue, routers typically canít make much power at low RPMs. So you end up trying to run a high RPM, at a low feedrate, and it usually ends up burning your wood or melting your tools. As a reference, on our full size Haas, we consistently broke 1/8" solid carbide end mills in aluminum due to running a high RPM to get the cutting power and not being able to match the feed rate. On wood, you can probably get away with shallow cuts with up to a 1/4" end mill, as long as the feedrates can be maintained to avoid burning.

- Neither of these really take into account using 3D printed parts for major structural components. Many machine operators can tell you that lack of tool/fixture rigidity can cause tons of phantom issues.†

Now, these would be things to keep in mind and shouldnít necessarily deter you from pursuing this (honestly, Iíve been looking into this as well). But the stuff Iíve learned in having run wood/plastics on a proper full size router would absolutely play into my decision making on a more hobby-style machine, and hopefully will be really useful for you as well.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Snuze: Needs another Swede

04/04/2019 at 17:56 |

|

The MPCNC is designed with a modular tool mount and there are plenty of laser adapters out there already. O f course limited to diode-laser units, as a CO2 laser tube is just too bulky and delicate to ride around on the head. In other news though, 5 watt diode lasers are now routinely under $300... of course a 5 watt laser is gonna lead to some slow-ass cutting. A tiny end-mill might actually be faster, although it probably wonít leave as clean a cut on foam-board. 10 and 15 watt diode lasers are available in on the comm odity market these days, but still arenít cheap. A dedicated CO2 tube laser unit starts to look like a pretty good deal when you price 15 watt diodes .

Foamboard planes are actually on my to-make list with one of these. I have a design that Iíve been CADing on and off for years that I might eventually finish if I have a tool to make it with.

TheRealBicycleBuck

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

TheRealBicycleBuck

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 18:00 |

|

The Maker Made popped into my feed the other day. What it lacks in precision, it gains in size.

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Snuze: Needs another Swede

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 18:00 |

|

I actually have 2 of the FliteTest planes built, though the ESC is damaged on one and I need to order a replacement. Still havenít flown them yet but now that spring is here and the weather is getting good, Iíll have them out soon enough.

Hmm, maybe I need to re-think my laser idea.† Or build it anyways and try a small cutter.† Iím sure lasers will come down in time, so itís probably still worth doing and just waiting on the laser.††

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> TheRealBicycleBuck

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> TheRealBicycleBuck

04/04/2019 at 18:05 |

|

A h, yes I saw that too. Fascinating idea, let gravity do as much work as possible...

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Levitas

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Levitas

04/04/2019 at 18:12 |

|

Iím aware that a 10 000 RPM min im um spindle speed is a bit high, T he Makita has a full electronic speed control, and can maintain torque at RPM... there are several projects out there that modify the factory speed controller to handle speeds as low as 3000 RPM... still a bit fast, but certainly less likely to melt tools. No servos on these, dead reckoning with big-ass steppers. P lenty of torque, just watch out for stalls...

A ll in all though, this makes the smaller MPCNC seem like a better bet, as it should be more ridged, and has the same axis motor spec with less mass....

gmporschenut also a fan of hondas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

gmporschenut also a fan of hondas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 19:18 |

|

Iím curious on the percision of both of these. T he mpcnc is a bit m or e accureate as as the rails are raised and free, but may have deflection. The lowrider wonít suffer as much, but shavings, may reduce precision as the guide wheels move along the side. No idea just some thoughts on the design.†

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> gmporschenut also a fan of hondas

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> gmporschenut also a fan of hondas

04/04/2019 at 19:25 |

|

Yeah, the LowRider is clearly more of a CNC Router table, the MPCNC is more like a 3-axis CNC mill... The LowRider really does a great job of bringing the parts cou nt and complexity down low, but with some sacrifices... The MPCNC is clearly limited in size of work and torque application... Which compromise to make... That is the question!†

tromoly

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

tromoly

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 20:00 |

|

Stay away from 3D printed parts on a machine that does cutting, the rigidity just isnít there. Buy a Shapeoko or similar (depending on work area needed) instead, youíll get better success.

Levitas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Levitas

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/04/2019 at 22:25 |

|

Might be decently manageable then. Iím one to enjoy tinkering on stuff like this, so if youíre the same could be a cool tool.